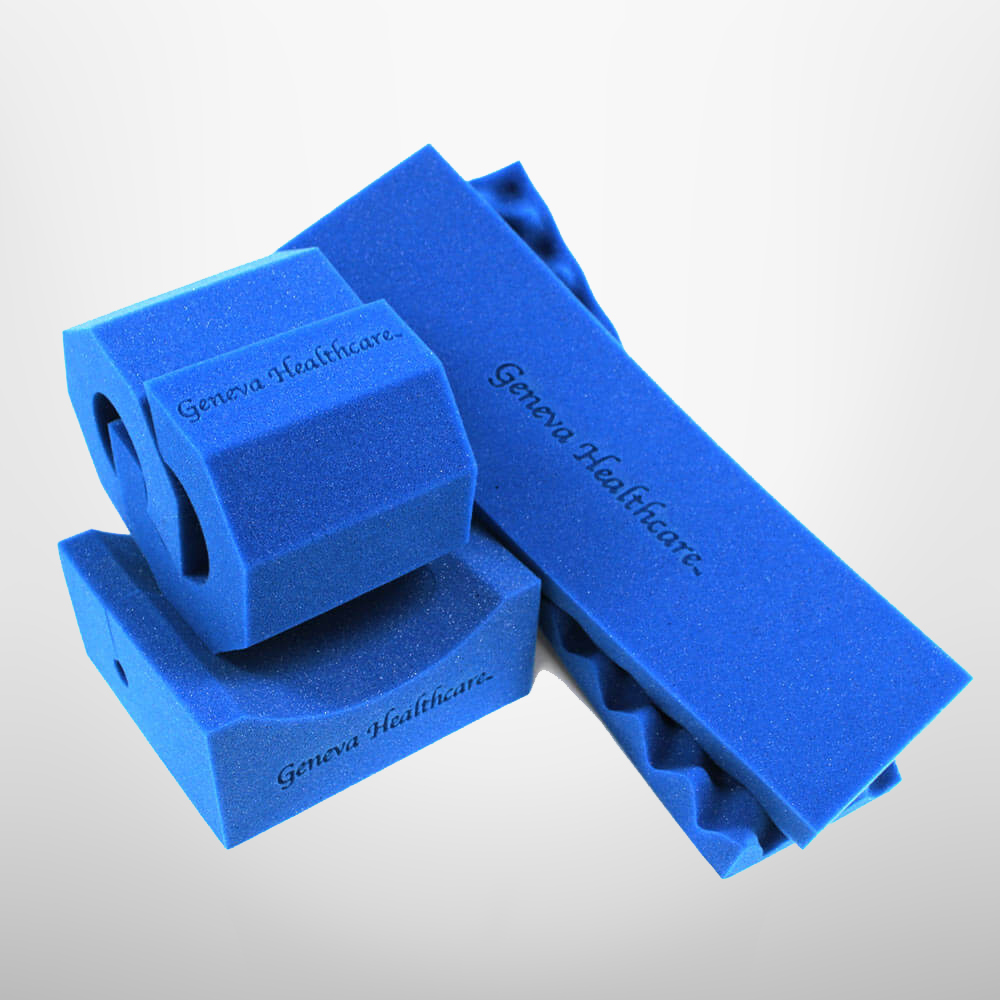

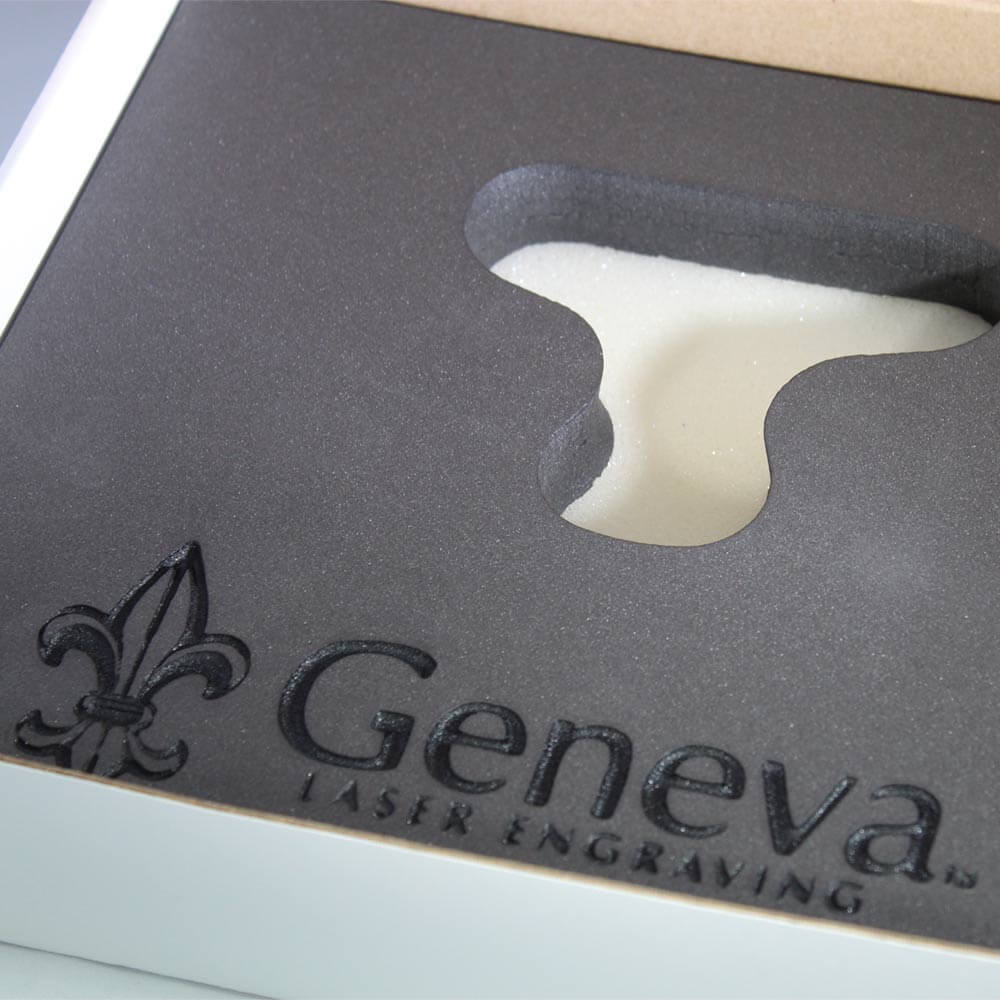

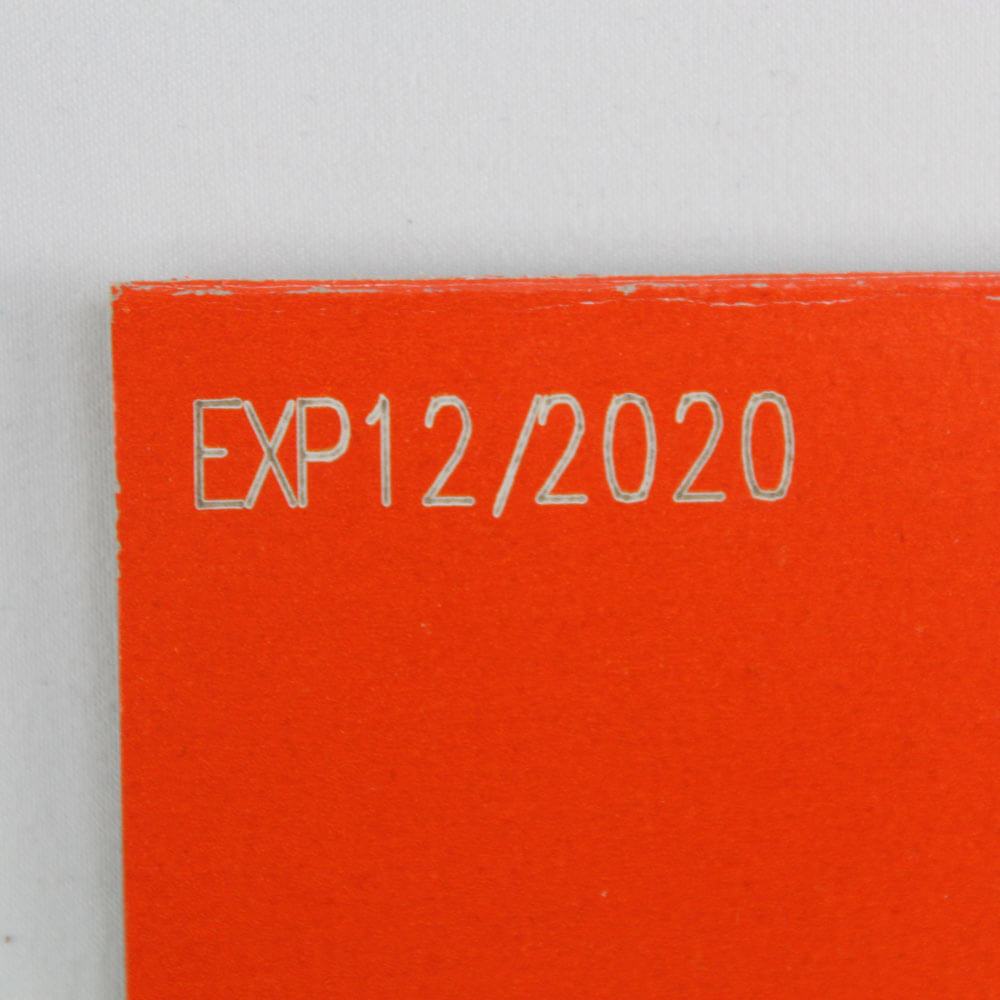

Medical Applications

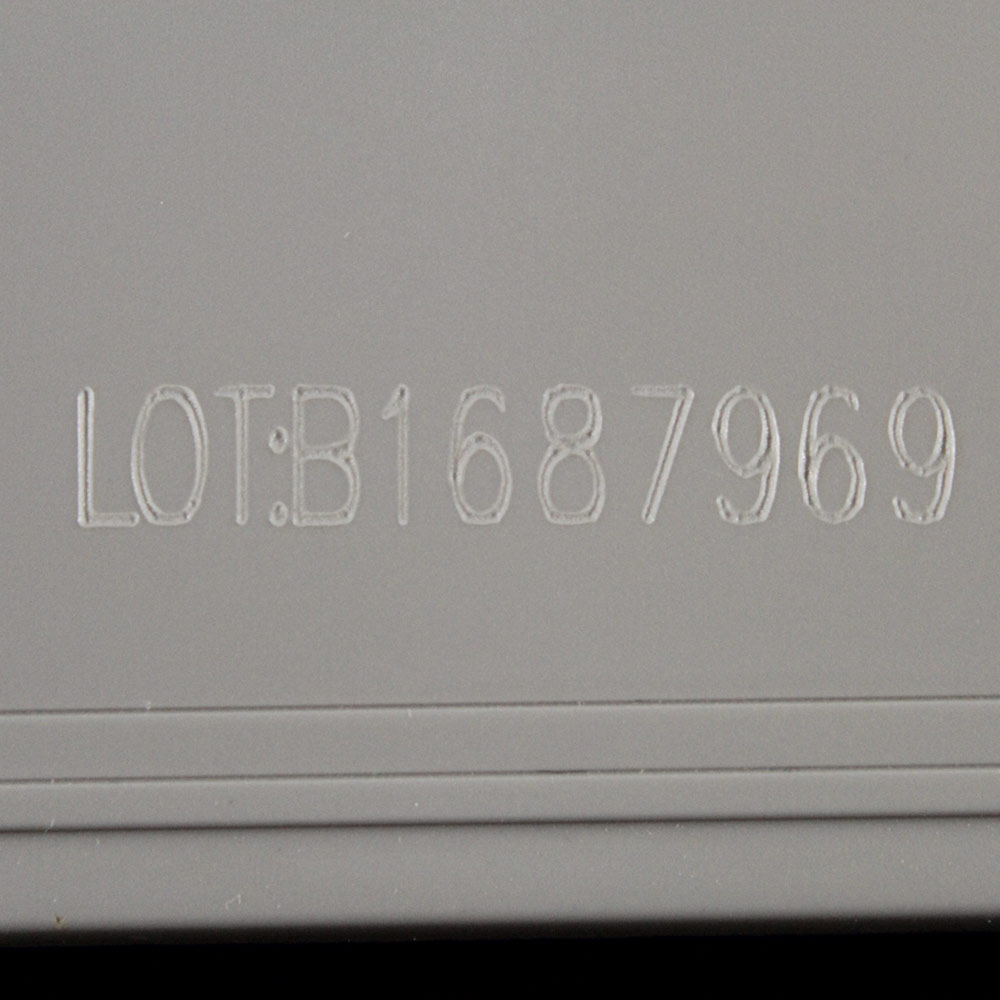

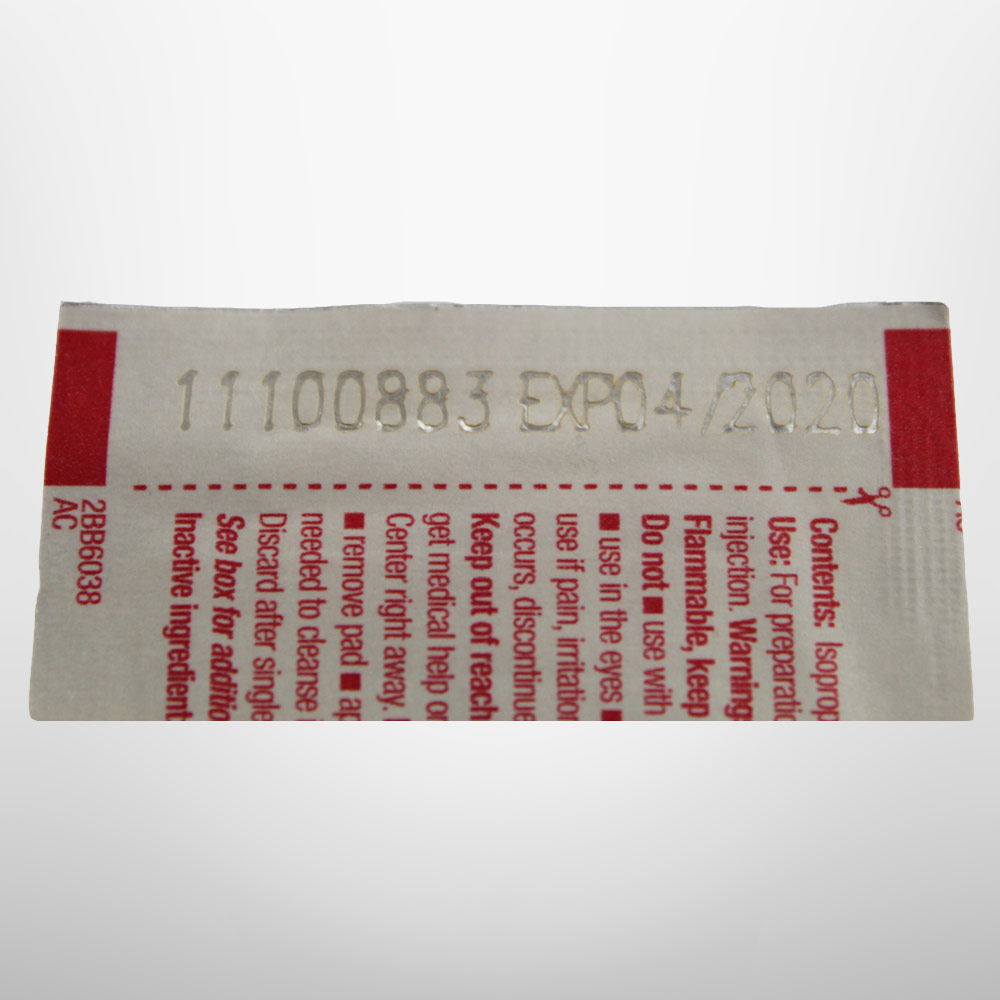

Laser engraving has a wide range of medical and healthcare applications. From engraving your facility’s name and logo into foam, to marking and coding, to part numbers or product names… find out how Geneva Laser Engraving can help.